Distributor Rebuild and Repair…

Grand Valley Tractor repairs and rebuilds around 20 distributors for tractors and street vehicles each year. Our rebuild process is very thorough and similar to how we treat carburetors:

1. Disassemble.

2. Soak for 24 hours in alcohol, NEVER in that caustic cleaner!

3. Dry for an hour in a 150°F convection oven.

4. Blast with baking soda, NEVER with sand!

5. Inspect/measure all parts.

6. Replace or repair parts as needed.

7. Reassemble.

8. Adjust.

We also make parts for them that you can't buy elsewhere. More and more, we've been designing and manufacturing replacement parts as recent tariff issues come into effect. This is done here…in Orwell, Ohio, USA…by Americans, for Americans. As we develop and release new parts, we'll announce them here on this website, so check back often!

1. Disassemble.

2. Soak for 24 hours in alcohol, NEVER in that caustic cleaner!

3. Dry for an hour in a 150°F convection oven.

4. Blast with baking soda, NEVER with sand!

5. Inspect/measure all parts.

6. Replace or repair parts as needed.

7. Reassemble.

8. Adjust.

We also make parts for them that you can't buy elsewhere. More and more, we've been designing and manufacturing replacement parts as recent tariff issues come into effect. This is done here…in Orwell, Ohio, USA…by Americans, for Americans. As we develop and release new parts, we'll announce them here on this website, so check back often!

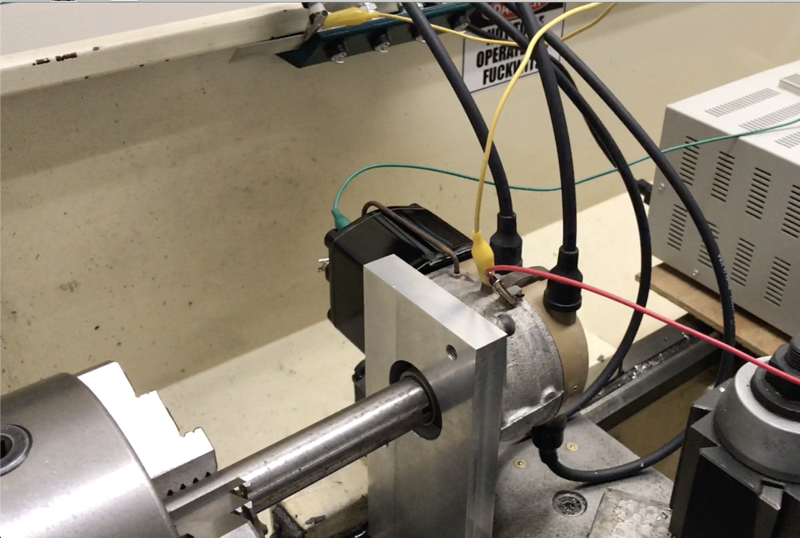

Here's some fixturing that we designed for use in our lathe to "tune" the resistance, capacitance and the inductance of ignition systems. This is critical when designing a new set of points, condenser or a coil in order to minimize point wear. We've included a pic of a prototype of the movable point we're developing.

Chinese

GVT

Final test of a rebuilt distributor is made simple with some fixturing we've developed.

Ported distributor cap for observation of the arc at the points.

We can test the advance curve on the early Ford "N" tractor distributor using our vertical mill and some fixturing that we designed. What we've seen is that the Chinese distributor shaft and advance mechanism is completely wrong when compared to Ford's original specs! We've observed this in every shaft from every supplier. Corrections coming soon!

Ever notice that the front bushing in Ford front mount distributors is always worn and the rear bushing isn't? Well, we know why, and we've found the correction for it! It turns out that Ford never balanced their rotor design! They did in the succeeding design (side mount) distributor in 1950. So, our new design is balanced. We also addressed the problem of the mis-indexed shafts coming from china while we were at it…so…two corrections in one! These are coming soon!

Original

Grand Valley Tractor "balanced" & "indexed" design

Grand Valley Tractor - 4115 Mayfield Road - Orwell - Ohio - 440-437-5572

Store Hours: Monday - Saturday 9AM to 5PM

Note: We no longer accept payment via credit or debit cards…sorry!